- Phone: 800-492-1252

- Fax: 440-368-3569

- E-mail: info@spartanwatertreatment.com

Corona discharge type ozone generators produce ozone in a electric arc or plasma between a dielectric and a metal electrode. Water entering this part of the ozone generator will create significant damage to the ozone generator and could be extremely dangerous. Since the ozone gas must be mixed with the water to be treated, the potential exists for water to enter the generator if the system is not properly designed.

As mentioned elsewhere on this web site, there are multiple ways to contact the ozonated gas with the water : side stream injection with a venturi , fine bubble diffusers and via a GasTran unit . In the latter two cases the pressure int eh ozone generator is higher than the pressure of the water in the system. This minimizes the potential for back flow of water in to the generator. In the case of fine bubble diffusers, the generator is normally positioned above the water level which makes back flow very unlikely.

In the case of a venturi eductor/venturi, the pressure in the water system exceeds the pressure in the ozone generator. The low pressure region of the venturi allows ozone to be introduced into the water stream despite this pressure difference in the main flow. In many cases the venturi is situated in a side stream that feeds into the main flow. A separate booster pump is used to provide the motive force to the venturi. If this pump were to fail, the pressure in the main line could back up into the ozone generator via the venturi damaging the ozone generator.

Given the potential for damage and possible safety concerns, a back flow prevention system is employed. The complexity of the system and the number of back-ups is usually determined by the size and cost of the ozone generator.

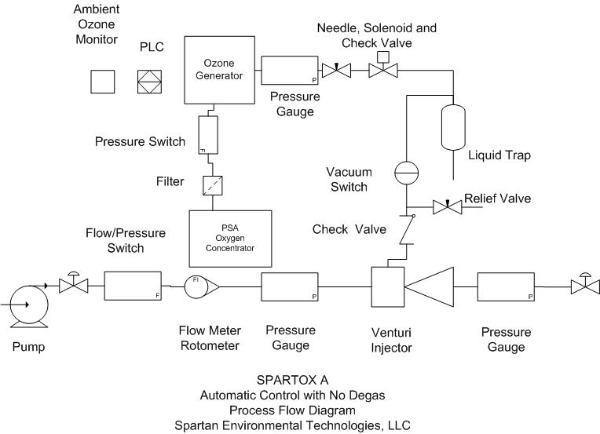

Check Valve: The simplest method to prevent back flow is to use a check valve on the gas line feeding the venturi. Check valves are not very reliable devices, although new versions without moving parts are being introduced. There should always be another back flow protection method added to the system.

Liquid Trap: The liquid trap is a device with a float that opens a valve when water enters the device. As a result, any back flow from the venturi can be directed away from the ozone generator and to a drain line. This is a fairly robust method, but if there is high pressure int eh liquid line the trap might be overwhelmed and some of the water could flow back to the generator.

Vacuum Switch: A vacuum switch can be placed on the venturi line. Since this line is expected to operate under vacuum, a positive pressure could mean back flow. The switch can be integrated with a fast acting solenoid valve that will close if a loss of vacuum is sensed.

A combination of the three methods discussed above should insure that back flow all the way back to the ozone generator is unlikely to occur. The flow sheet below illustrates the application of these three techniques in an ozone water treatment system.