Ozone-based in situ chemical oxidation (ISCO) involves injecting ozone subsurface in order to transform certain chemical compounds to make them less toxic. Ozone can be used by itself or it can also be combined with other peroxide to create an advanced oxidation process (AOP). An AOP is any process that creates the hydroxyl radical. Ozone by itself is a selective reactant targeting specific chemicals. The hydroxyl radical is not specific and will attack virtually all organic molecules.

There are many advantages of ozone-based ISCO. Higher concentration of ozone can be injected, ozone is more stable in the gas phase versus the liquid phase, diffusive transport is higher, and higher velocities can be achieved. Disadvantages include potential for poor distribution of ozone into the subsurface and the limited effective distance from the injection point that can be achieved.

There are several benefits of using ozone-based in situ chemical oxidation. The injection of air beneath the water table volatilizes certain organic compounds, supplies oxygen for aerobic bacteria, and can mix the ground water. Since ozone is a strong oxidizer capable of directly transforming many chemicals to less toxic substances, ozone can enhance the effectiveness of air sparging. Here is comprehensive information on ozone and its properties.

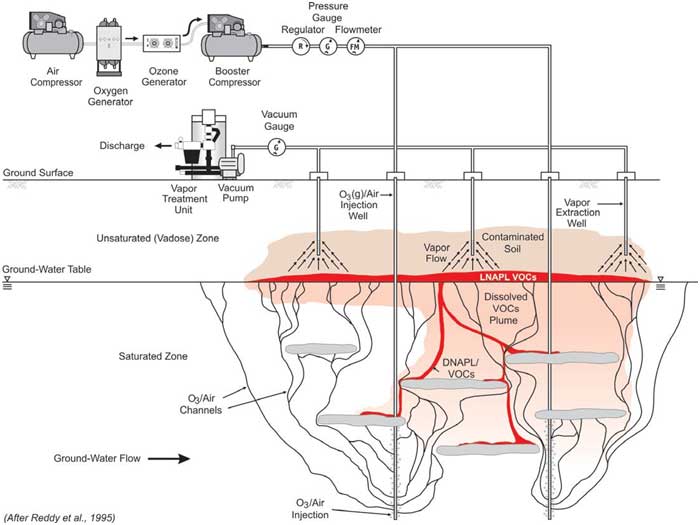

In many cases where ISCO is practiced, ozone is injected as a gas subsurface with air as illustrated below.

When ozone is introduced with air sparging, the ozone must diffuse away from the injection point to reach the contaminants or be carried by buoyancy towards the surface. Design of a sparging system requires and understanding of the soil characteristics and the nature of the contaminant distribution. The design should be left to engineering specialists. ISCO based advanced oxidation processes are more complicated since once the hydroxyl radical forms, its lifetime is measured in micro seconds.

As a result, it cannot travel any distance. In the case of ozone peroxide, for example, the peroxide would be injected first. After peroxide is injected, then the ozone is sparged into the ground. This allows the hydroxyl radical to form as the ozone diffuses away from the injection point. The concentration of peroxide selected is critical in maximizing the range of a given injection well. The pump and treat approach may be a better option for the use of advanced oxidation in most cases.

Find thorough information of ISCO in the EPA Engineering Issue on In Situ Chemical Oxidation by Scott G. Huling and Bruce E. Pivetz.