Oxygen Recycle Systems

As noted in other sections of this website, typical ozone generators produce anywhere from 6-15% ozone from oxygen feed. This means that 85-94% of the oxygen is wasted if not recovered. Since oxygen generation or purchase is a major expense for making ozone, recycling of oxygen after the water treatment process has been considered over the years. It is also important to note that producing more concentrated ozone increases both the capital and operating cost of an ozone water treatment system. This further makes recycling of interest since producing ozone at lower concentration might be more economical if the oxygen can be recovered.

Three concepts have been considered for oxygen recovery in ozone water treatment applications:

In the first case, oxygen from the contact vessel which is saturated with water and at atmospheric pressure can be used in some other process at the facility. In a wastewater treatment plant for example, the oxygen could be fed to a blower for an activated sludge process. Oxygen is more effective than air in these situations and since the oxygen would otherwise be wasted, this is a very cost effective application for the spent oxygen. This type of oxygen recovery application is practiced in some facilities. Other applications exist in the pulp and paper industry. Unfortunately, in many water treatment applications effective use of the ozone in other processes is not possible.

The second option is to take the oxygen from the ozone contact vessel and use it to feed the ozone generator. This is difficult to do since the oxygen is full saturated with water, may contain hydrocarbons stripped from the water and is at atmospheric pressure. Ozone generators require extremely dry gas, -70 degrees F or better, low impurity levels and pressures from 10-20 psi. The cost for drying, cleaning and increasing the pressure of this off gas has not been found to be economical.

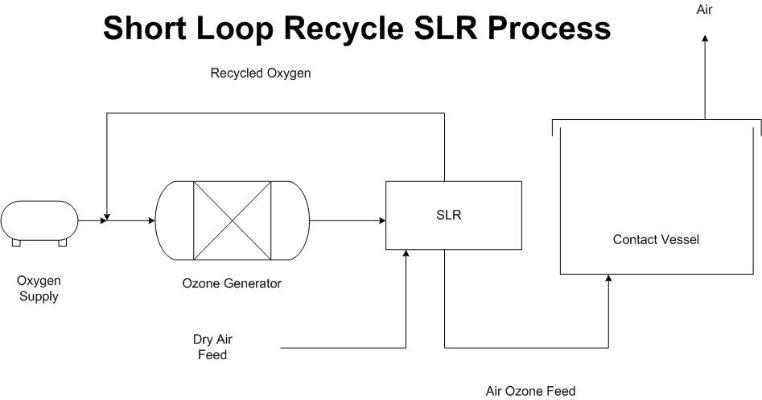

Recently, Air Products and ITT WEDECO have disclosed a process call “Short Loop Recycle”. In this process, shown below, oxygen is fed to an ozone generator. The oxygen ozone gas mixture is then fed to an adsorption bed where the ozone is adsorbed and the oxygen passes through. This oxygen is recycled back to the ozone generator. Adsorption bed is cycled to strip the ozone from the by a carrier gas, dried air. The air ozone mixture is then fed to the contact vessel where the air, after removal of any remaining ozone, is vented to atmosphere. The developers claim that ozone concentrations of 1-12% can be achieved with this process. It is not economical possible to exceed about 3% ozone in air directly.

The claimed advantages of the process include: