Ozone transferred is difference between the amount fed (ozone feed) and the amount he leaves the system (ozone out). Ozone transfer efficiency can be expressed as follows:

Transfer Efficiency (TE) ={(Ozone Feed) – (Ozone Out)}/(Ozone Feed)

The transfer efficiency is effected by various factors including bubble size, temperature, pressure, gas/liquid ratio, concentration of ozone in the feed gas(related to ozone generator output), water chemistry, etc. The following relationships between key variables and TE exist:

The design of the mixing/contact system are important for the TE. Different types of mixing systems have application given site specific conditions and economics. In the case of fine bubble diffusers the flow pattern through the contact vessel and the depth of the diffusers are critical to the TE. Beyond the normal factors effecting TE, the configuration of the side stream injection system will have an impact on TE, e.g. removing gas immediately after the injector or in the contact chamber.

Background

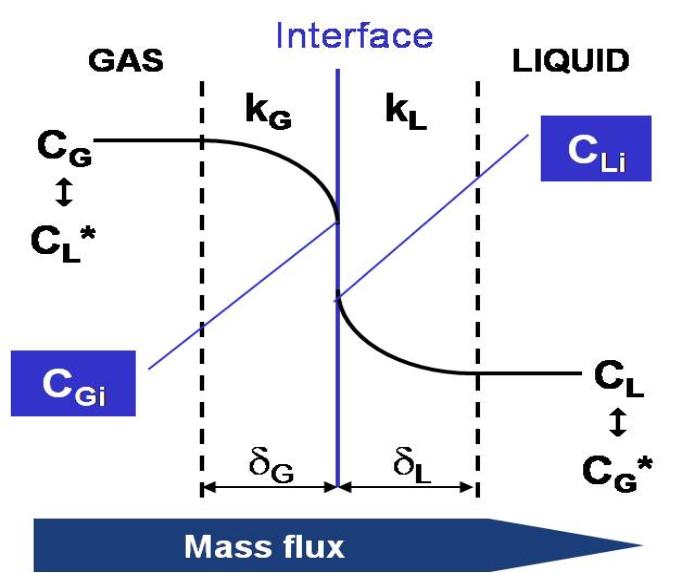

1. Ozonation is an absorption process

2. Mass transfer rate dependent on

Physical properties of phases

Concentrations at the interface

Degree of turbulence

3. Two-film model (Referring to the diagram below)

N = (kL x a) x (CL*-CL) x VL

CL* = f(CG, P, T) – Henry’s law

CL = f(mixing conditions)

kL.a = f(hydrodynamic & operating conditions, reactor configuration)

CL: Concentration of Ozone in Liquid

CG: Concentration of Ozone in Gas