- Phone: 800-492-1252

- Fax: 440-368-3569

- E-mail: info@spartanwatertreatment.com

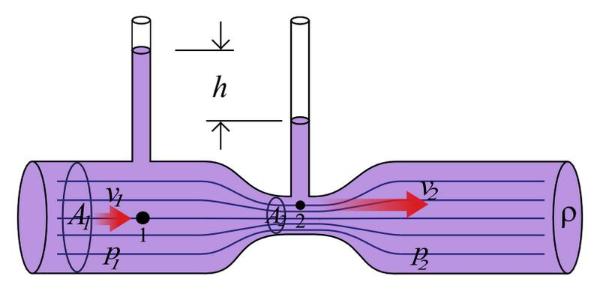

A venturi injector is a great method to use when needing to inject air, oxygen, or ozone into water to mix fluid with air. If a pump forces the fluid through a tube connected to a system consisting of a venturi to increase the water speed (the diameter decreases), a short piece of tube with a small hole in it, and last a venturi that decreases speed (so the pipe gets wider again), air will be sucked in through the small hole because of changes in pressure. At the end of the system, a mixture of fluid and air will appear. The simplest apparatus, as shown in the diagram, is a tubular setup known as a venturi tube or simply a venturi. Fluid flows through a length of pipe of varying diameter. To avoid undue drag, a venturi tube typically has an entry cone of 30 degrees and an exit cone of 5 degrees. Another method for dissolving ozone into water is the fine bubble diffusion method.

The device works via the Venturi effect, an example of Bernoulli’s principle. The Venturi effect is a phenomenon that occurs when fluid flowing in a pipe is forced in and through a narrow section yielding a pressure decrease with a velocity increase. In the case of incompressible fluid flow through a tube or pipe with a constriction in it. The fluid velocity must increase through the constriction to satisfy the equation of continuity, while its pressure must decrease due to conservation of energy. Thus, the gain in kinetic energy is supplied by a drop in pressure or a pressure gradient force. Watch a video describing how the Venturi effect works.

Contact Spartan if you have questions about venturi injectors and industrial ozone water treatment systems.